safety intro

Safety is extremely important for any business. Accidents cost companies thousands, if not millions, of dollars each year. It's in your best interest to pay close attention in this section. Most accidents are because of the actions of the individual involved; and usually avoidable. You should never be risking your life for your job. Always put safety first. That's cliché, but true. Once you start a task it's easy to keep going or forget about safety. Instead, when you arrive on the job think about the task and how it could affect a safe working environment. What are some hazards? What protective equipment do I need? How can I avoid putting myself in danger? Get all of these questions solved and safety equipment on before starting work a on task. If it

doesn't happen first, there's a good chance it won't happen.

-

Why Is Safety Important?

Safety should be the number one priority and matter to you, and your employer for the following reasons:

You

People care about you. Without healthy, productive workers in society, business operations can't run successfully. In any business the people who work in it are the most valuable asset. Take care of yourself so you can take care of your business and family. An accident can happen in seconds and change your life forever, or even end it.

Insurance

Insurance rates continue to rise, making it expensive for employers to operate. Keep your rates down by being safe on the job. High company expenses means more pressure on management and less benefits to the employees. Keep expenses lower by being safe and effective on your job.

Compliance

There are requirements for employers to provide employees with injury and illness prevention programs to keep them safe and healthy on the job. Please pay attention to your training so your workplace is up to standard and you can be a voice to others who aren't following the rules or working safely.

Financial Loss

Injuries cost companies a lot of money, both directly and indirectly.- Direct Injury Cost:Insurance deductibles and increased premiums, medical expenses, physical therapy and/or rehab, repairs for damaged tools and equipment

- Indirect Injury Costs: Extra wages not covered by worker's compensation, training a replacement, overtime wages from related employees with paperwork and reports.

-

Common Causes Of Accidents

Confidence

Accidents often happen when a worker gets overly comfortable or confident doing a task. Use safety practices as if it is your first time completing a task. Never assume things will always go as planned by getting complacent. If it can go wrong, it will.

Distractions

If a customer needs your attention then stop what you're doing. If you need to focus then let the customer know that you'll be right with them. You can also have distractions from your personal life; try to separate home problems from work so you can get your work done safely. If you're struggling mentally, then talk to a supervisor so you're not put into an unsafe situation.

Shortcuts

We all want to get our job done, especially if you're on commission. The cost of an accident is much greater for everyone. Slow down, remember your training and use it. Do not be overconfident or attempt to show-off. Do not push your ability and equipment boundaries to get things done quicker.

Messy Workspace

Keep your workspace organized and clean. This limits tripping hazards and keeps your job going safely and efficiently. Don't leave items in walking areas, this includes work facilities as well as on the job.

Directions

Listen to customers/contractors/supervisor/etc. If you don't understand, clarify the directions to make sure you understand them fully. Always have a plan when starting a project and make sure everyone knows the plan and fully understands it.

Training

Always use your training. Refer to the tools, equipment, and products you know and have been trained with. Over extending your expertise can contribute to an inefficient workplace and accidents. If you don't understand something or need further instruction, stop immediately and, seek more information. Do not resume a task until you're sure you can do it without injury. -

Hierarchy of Controlling Hazards

The hierarchy of controls was created by safety professionals to help deal with hazards on the job. Look at every hazard using the hierarchy of controls with the more desired option always being to eliminate the hazard. The least desired outcome is personal protective equipment because the hazard is still present to the worker. -

-

Hierarchy of Controls in Action

A worker needs to get to a dormer window on the edge of a roof and the ground is uneven making it difficult set up a ladder. To eliminate the hazard, the worker could pull the window inside to work on it. If that option is unfeasible, the worker could substitute the hazard by a pole system from the ground. If that option is unfeasible the worker could use engineering controls such as ladder levelers to clear the roof's edge and reach the dormer. If that's not feasible, the worker could use administrative controls by having someone foot the ladder or another company policy. Finally, if none of these controls are feasible, the worker could wear personal protective equipment such as a personal fall restraint system to access the roof. While this scenario may not be completely common, you should always be looking for a better, safer way by eliminating options from more desirable to least desirable. The worker should also reach out to more experience worker's for more ideas, better training, etc. -

-

The Risk Assessment Matrix

On any given task and on any given job site the hazards can change. It's important for a worker to focus their attention on what's important. Using the risk assessment matrix, a worker can put their attention on what's the most common incident with the highest consequence. This assessment weighs the opportunity of probability to the severity of an incident by using basic multiplication to help the worker focus on the highest number. Note: These assessments can change their measurement formulas so make sure you are correctly understanding the greatest and most frequent risk. -

-

Job Hazard Analysis (JHA)

A JHA (sometimes called job safety analysis, or JSA) is used to help worker's document and think through their decisions on the job. A JHA can look a million different ways but they all serve the same purpose, to keep you safe by thinking through your actions and documentation for safety measures. These forms can be incredibly simple for standard company procedures or more complicated for tasks that aren't seen in the regular activities of the company.

Standard Company Procedures

If you work for a company who uses ladders to get to second story homes then your company would most likely have standard operating practices and procedures. Even though this is a common business practices it's still a hazard. Using a simple job hazard analysis you could simply acknowledge the ladder hazard and refer to company standard operating practices for working with and on ladders.

Irregular Company Procedures

If you're working for the same company who has a unique job that needs a lift, this would be an irregular company procedure. Since you're not on lifts frequently during normal procedures this would be a good opportunity to use a more extensive job hazard analysis. Use this as an opportunity to look at the task, use the risk management assessment matrix, and look at the hierarchy of controls to solve the hazard. -

Types of Hazards

-

Physical Hazards

Musculoskeletal Disorders

Musculoskeletal disorders are commonly known as arthritis, tendinitis, carpel tunnel, fibromyalgia, etc. These disorders can have symptoms that include swelling, pain, weakness, stiffness, joint noises, and decreased ranges in motion. This can develop over time by overuse of the same muscles and ligaments. Listen to your body when it's telling you to slow down or stop. Plan your tasks with the proper equipment, correct personal protective equipment and a plan to rest or rotate aggressive tasks.

Repetitive Motion

Repetitive motion refers to a task that requires a worker to repeatedly move their body. This can be an array of different things in different services and tasks. Before starting your task plan to take breaks, switch positions, or rotate the task with other workers. This can help prevent short term fatigue and long term damage.

Vibration

Vibration is a common issue with pressure washers and other power equipment. Try to limit a worker's time spent on a heavily vibrating task by rotating crew members. Also make sure that equipment is properly maintained and set to the correct pressure to minimize vibrations. Signs of health effect from vibration include but not limited to back pain, motion sickness, bone damage, digestive issues and more.

Struck

You can be struck by vehicles, falling objects, machinery, and other equipment. Even if you're the safest worker on the job, you're still subject to others around you. When pulling up to any job make sure you're observing what's going on around you. Are there things that could fall? Are there a lot of moving vehicles? Is there moving equipment/machinery? Bring these hazards to attention with coworkers so you work together on limiting and controlling them.

Fatigue

Worker fatigue can happen quickly and dramatically in extreme weather. However, sometimes a worker repeating the same strenuous task can develop fatigue. When a worker becomes fatigued, they might not make the best decisions or have the strength to do a simple task correctly. The more extreme the weather and the task, the sooner the employee may be feeling fatigued or weak. If you're feeling weak, fatigued or exhausted from your work then it may be time for you to take a break. Do not push through these feelings because it could cause a much more serious incident that could have been prevented. Tell others how you're feeling so they can keep an eye on you, get rest, and drink water. Check the weather before work, know your upcoming schedule and plan ahead so you can be well rested, fed, and mentally clear for work.

Lifting

Plan the Lift- Appoint one worker to plan the lift

- Ensure you have enough workers to help safely distribute and move the load.

- Match workers evenly with similar ability and height

- Make sure each worker knows their responsibility by rehearsing the lift.

When Lifting- Know the weight of what is being lifted

- Don't push your limits by attempting to lift something that's too heavy, or lift awkward things.

- Always clear away obstacles in the path you're moving.

- Get a good grip and keep your elbows close to your body.

- Use your legs, not your back.

- Always keep your chin down, feet shoulder width apart.

- Keep the load close to your body, and never twist.

-

-

Weather & Nature Hazards

Plan ahead by checking the weather before you head out. Things like wind, lightning, rain, snow, ice, heat, and other weather conditions all play a part in the safety of your work.

Cold

When working in the cold:- Wear a warm hat - most body heat escapes in your head.

- Wear multiple layers - you can shed layers if you heat up.

- Wear gloves and use glove warmers.

- Wear slip and water resistant shoes.

- Watch out for icicles and never walk below them.

- Watch out for ice/snow and have a coworker hold your ladder.

- Take shorter strides in stormy weather to avoid tripping/slipping.

- Monitor each others physical condition and work in pairs.

- Take short breaks frequently in a warm, dry area to warm up.

- Try to work in the sun and schedule around the warmer parts of the day.

- Use heaters where possible.

- Drink warm drinks, and avoid alcohol.

- Plan ahead and listen to your body when it's saying something isn't right.

Heat

When working in the heat:- Take extra breaks to avoid fatigue or a heat stroke in extreme heat.

- Drink extra water/hydrating liquids.

- Avoid drinks that are diuretics such as coffee, tea, energy drinks, and alcohol.

- Wear PPE to cover skin, use sunscreen, and hydrating towels.

- Be aware of heat exhaustion signs such as headache, dizziness, nausea, vomiting, rapid heartbeat, sweating.

- Call 911 if someone stops sweating, or becomes disoriented, this means they're most likely having a heatstroke, which can be fatal.

Driving

When driving in dangerous weather:- Drive slower, it takes longer to stop.

- The roads are extra oily after the first seasonal rain, or after drought.

- Take extra precaution watching for pedestrians

- Have a coworker help you back up.

- Have a coworker help you back up.

- Start turn signals well before the turn.

- Make sure your windshield and mirrors are clean.

Earthquake

You may or may not have earthquakes in your area. Read this section regardless of whether you're traveling someday. Use common sense to stay in a place that is safe from anything that can fall. Once the shaking stops, remember that there will be aftershocks that will continue to shake.

If you're inside:- Drop, Cover, and Hold under something sturdy.

- If there is nothing to get under, get in the corner of the room.

- Stay away from windows/glass or anything that can break.

- Stay inside until the shaking stops.

- Stay outside and move away from buildings, trees, and utility lines.

- If a building looks damaged stay out of it until it's inspected.

- Maintain four points of contact with the ladder.

- Slide your hands to get down the ladder quickly without letting go.

- Follow inside/outside directions depending on where you are.

- Consider staying there until the shaking stops.

- Find something to hold onto if possible; keep your body low and away from the edge.

- Once the shaking stops, immediately get off the roof safely.

- Follow ladder directions if needed.

- Pull over as safely as possible.

- Don't stop under buildings, trees, utility lines, or over/under bridges.

- After the earthquake, proceed with caution, as there could be road damage.

- Do not light a match/lighter. Gas lines can burst and explode.

- Move minimally to avoid kicking dust and cover your mouth.

- Find something loud to tap for rescue workers.

Storms

Try working around the weather and planning ahead by checking the forecast beforehand. Watch for severe thunderstorm watches, and warnings.

- Take shelter somewhere sturdy that will protect against lightning, hail, high winds, flooding, and tornadoes.

- Avoid windows, electrical sources, plumbing and objects that could fall.

- Keep your pets with you.

- Avoid metallic objects.

- Stay away from boats and water.

- If you hear thunder, your're close enough to be struck by lightning.

- Tune in to local broadcast for weather updates.

- Take immediate action before storms hit.

-

Chemical Hazards

Chemicals are a part of our everyday lives, especially in the cleaning industry. While they can be incredibly helpful in our lives, they can also become health hazards if not properly used and handled. In this section we'll go over getting the right information for safe handling of different chemicals you might be working with. Remember that your skin is your largest organ and it's incredibly absorbent. Chemicals can get into your body by ingesting, inhaling, absorption, injection or skin absorption. This can make someone severely sick, have long term health issues, or even death. Health hazards can be either acute or chronic.

Types of Symptoms

Acute

Acute symptoms usually happen suddenly but go away after a short time, usually a few days or weeks. Acute conditions can be avoided by using the correct personal protective equipment and using proper handling procedures.

Chronic

Chronic symptoms happen slowly and can worsen with time, especially with consistent expose. It's important to protect yourself from chronic conditions because you might not know there's an issue until it's too late. Using the correct personal protective equipment and proper handling procedures can help avoid chronic symptoms.

Symptoms

If a worker is experiencing dizziness, eye irritation, rashes, difficulty breathing, feeling nauseous, or other symptoms that would indicate chemical exposure, report to a supervisor immediately. Get the appropriate first aid materials and refer to the Safety Data Sheet of the chemical, and contact a poison control center if applicable.

Getting Into The Body

Ingesting

Before eating, drinking, smoking, or making any movement near your face, be sure to wash your hands with soap and water for at least 20 seconds up to your elbows. When taking off PPE, be sure to remove without cross contaminating.

Inhalation

Inhaling is common from chemical fumes, vapors, gasses or dust. This can be avoided by wearing the proper respirator to filter these hazards out.

Absorption

Avoid chemical contact with your skin by wearing proper PPE recommended by the manufacture. When removing your PPE, be sure to remove without cross contaminating.

Injection

This is usually the least common way chemicals enter the body in the workplace. This can happen from cuts or sharp penetrations to the skin, allowing a chemical to be directly injected into the individuals bloodstream.

Safety In The Workplace

Safety is the workplace begins with the employer educating employees and providing the proper tools to keep a safe workplace. Researching chemicals and finding the safest solution for the task is the best place to start. Second, keep the chemicals consistent so workers know proper handling and have the correct personal protective equipment. When considering chemical use, use the hierarchy of controls to find the best solution for safety controls.

Classifications, Labelling, Data, and Communication

The hazard communication standard was created by OSHA to simplify product hazards to users. The communication is done through the globally harmonized system Globally Harmonized System of Classification and Labelling of Chemicals (GHS) and Safety Data Sheet (SDS). This was created with the belief that workers and product users have the right to know what's in the products they're using and how to protect themselves.

Globally Harmonized System (GHS)

The GHS is an international effort for using pictograms to to communicate hazards around the world. See the pictograms below. If you see these on any products you're using then make sure you are familiar with the product and how to safely use it -

-

Safety Data Sheet (SDS)

Safety data sheets are used for a more in depth look at a product than just a pictogram. If you're unfamiliar with a product and you see a pictogram then you should look over the safety data sheets. It is required for employers to provide these for their workers. You can also find these on the manufacture's website. The SDS is broken down into 16 different sections for the user to find the information they're looking for.Section 1: Identification

Section 2: Hazard(s) Identification

Section 3: Composition/Information on Ingredients

Section 4: First-aid Measures

Section 5: Fire-fighting Measures

Section 6: Accidental Release Measures

Section 7: Handling and Storage

Section 8: Exposure Controls/Personal Protection

Section 9: Physical and Chemical Properties

Section 10: Stability and Reactivity

Section 11: Toxicological Information

Section 12: Ecological Information (non-mandatory)Section 13: Disposal Considerations (non-mandatory)

Section 14: Transport Information (non-mandatory)Section 15: Regulatory Information (non-mandatory)

Section 16: Other Information

-

Take a moment to look over some SDS Sheets to familiarize yourself with the information. Ask your employer which chemicals you should be aware of.

-

Storing Chemicals

The following are safety guidelines to follow in addition to safety data sheets.- Properly rated fire extinguisher should be present and accessible in storage area.

- Keep storage out of direct sunlight.

- Do not smoke, eat, or drink near chemicals or storage areas.

- Do not weld or use other sparking/heat devices near chemicals or storage areas.

- Ground any flammable storage containers when transferring product.

- Keep storage area cool and dry to avoid vapors and other hazards.

- Keep all containers clearly marked and organized.

- Keep containers closed when not in used.

- Clean up spills immediately and properly discard to the SDS standard.

- Store and use in well ventilated areas to avoid vapors.

- Keep the SDS updated and reviewed regularly.

Important Terms

Below are terms that are common to hear while working around chemicals. It is important to know that almost all chemicals can become dangerous in the right circumstances. Understand these terms to protect yourself and others around you.

Toxicity Is the damage point a chemical can cause damage to a living organism, organ, or cell. Substances can get into your body by inhaling, ingesting, skin absorption, and injection. In the workplace this usually means through the eyes, mouth, skin or respiratory track. The toxicity of a substance someone might encounter can be difficult to measure depending on their age, weight, and gender. Avoiding toxic effects starts with wearing the correct PPE for the substance. Familiarize yourself with the product so you understand the effects it could have on your body beforehand. Even water can have toxic effects on the human body.

Flashpoint

Flashpoint is the temperature at which a substance can create a vapor sufficient enough to ignite in the air. Some substances have a highly volatile (high and low) flashpoint such as gasoline. This means it can ignite from from a major swing in temperatures all the way down to -43 degrees. Storing substances in the wrong temperature can create a toxic and highly flammable vapor in the air. A simple spark could create a deadly explosion. The lower the flashpoint, the easier it is to ignite the substance. The fire point is usually a few degrees above the flashpoint. Make sure you know the proper temperature to store your products safely and successfully.

Combustible Liquids

Any liquid that has a flashpoint at or above 100°F(37.8°C) would be considered a combustible liquid.

Flammable Liquids

Any liquid that has a flashpoint below 100° (37.8°C) would be considered a flammable liquid. This means the liquid should be handled with extra care because it can combust at lower temperatures. -

-

Exposure/Exposed

This means an individual has been or could be susceptible either by accident or possibility from use of ingesting, inhaling, injection or skin absorption of a chemical. Use the safety data sheet for first aid measures and call a poison control center for further help.

Water Reactive

A water reactive chemical can create a flammable gas or health hazard when exposed to water.

Boiling Point

This is the temperature at which a liquid would become a vapor. The evaporation rate is rate of speed at which the material becomes a vapor at a given pressure and temperature. This is why it's so important to listen to the manufactures storing procedures.

Biological Hazard

Biological hazards are substances that threaten living organism, in this case humans. These are known as bloodborne pathogens which could be a virus, toxin, spores, fungi, bacteria, or a parasite. These pathogens can pose a great threat to humans when present in blood, organs, or tissue. These hazards can be traded human to human by open sores, cuts, abrasions, acne, blisters, or any other type of broken skin. They can also enter the body through contact with open mucous membranes such as the eyes, nose, mouth, or open skin. The more commonly known bloodborne pathogens are hepatitis b and human immunodeficiency virus (HIV).

-

Biological Hazard Symbol

This symbol was created to advise others of the dangers that could be inside the bag or container. Handle any item with this symbol on it with care and the proper PPE to avoid cross-contamination infection. This symbol should be present on any container that stores, transports, or ships blood or other material that could potentially be infectious. Containers should be fluorescent orange or red/orange with this symbol on it. Bags used to dispose of potentially infection martial are red with the symbol on it. -

-

Protecting Ourselves & Others

While being exposed to someone else's blood is is unlikely, it could happen in an emergency situation. Let's look at some practices we can do to avoid exposure to biohazards.- Assume all blood and bodily fluids are contaminated.

- Properly stock first aid kits, including gloves and other PPE.

- Wear gloves when handling any first aid response on someone.

- Never reuse or share needles, scalpels, first aid supplies, gloves, or other PPE.

- Practice good hygiene

- Keep the workplace clean and organized.

- Use engineering controls and PPE as a last resort for hazards.

- Avoid sharp objects including broken glass.

- Don't eat, drink, smoke or touch your face until you've thoroughly washed your hands.

-

Fire Hazards

Fires start when heat, fuel, and oxygen are combined. Keep these three elements apart as much as possible and be sure to recognize the hazard before these are combined. While on the job you need to avoid connecting fuel and a starter/igniter. The fire triangle is used to give you a visual on the elements of a fire. Be aware when these could accidentally combine on a job and create a fire. -

-

Fire Danger Index

The fire danger index is a published calculated number to notify the public of current finger dangers in the area. The index is calculated based on weather, topography, fuel, and risks of any potential events. Things like drought, temperature, wind, humidity, soil moisture, lightning strikes, overgrown vegetation and more are taken into account for the final number. These are usually posted regularly, sometimes daily by fire departments. While we should always use precautions for fires, the index might bring extra attention and heightened awareness to hazards and surroundings. Look for your local fire danger index to help you make decisions on the job relating to potential fire hazards.

Fight or Flee

Only you can decide when to fight a fire or flee the area. Your number one responsibility is safety. This includes yourself and others. When making this decision quickly, understanding the stages of fire growth can help you make a decision. If you have resources near (water or a fire extinguisher), it might help you make the decision to fight the fire. Other factors like how much heat, fuel, oxygen, time etc. are present will help you decide. Fire growth is broken down into several stages. When fighting a fire, the most ideal time to fight it is in the incipient stage. This is fighting it in the ignition phase. After the fire ignites, the growth phase has followed. Once the growth has gotten past the point of you being able to control it within your immediate resources, you need to leave. A fully developed fire is usually past the point of being able to control the fire. Remember that the fire can eat up your oxygen and cause unconsciousness. When you make a decision to flee, stick to it and don't backtrack, get yourself and others to safety.

Stages of Fire Growth

-

-

Prevention

Recognizing fire risks comes down to recognizing where a heat source (or ignition source) and fuel source could accidentally meet. This could mean keeping exhausts away from dry fuel, keeping flammables away from ignitions/heat, or water away from electricity. Before a project starts we should be aware of what we can do to keep the job safe. When arriving on a job:- Look for fire hazards and hose spigots.

- Where's a fire extinguisher and what kind?

- Always know where your bucket is.

- Keep equipment exhaust away from any objects, even if you assume they aren't flammable.

- Are there electrical sources that could get wet?

- What's and good escape route and a safe place to meet?

- Know your client, would they be able to escape?

- Know the job address for emergency services.

- Where are the keys to the work vehicle for an escape?

Types of Fires

Fires are broken down in a few different types to help fire fighters properly respond to the fire. It's important to understand different fires because they can require different measure to put them out. Sometimes adding water can help it grow and or create bigger hazards. Different fires can require different types of extinguishers as well. Read the following to get an idea of different fire types.

Type A: Combustibles

Rubber, wood, dry grass, cloth, paper, plastics, and other materials that burn easily. These types of fires can be started from excessive heat igniting something flammable. If you smoke make sure you do it away from a fuel source and your smoke is put out completely in a designated ash tray. If you don't have an ash tray, submerge the smoke in water and break it apart. Hot exhaust from motors can also start fires. Do not drive vehicles through dry fuel. Remember that machines can vibrate towards fuel sources even if you start them in a safe place. Do not put a hot exhaust or equipment down in a dry area.

Type B: Flammable Liquids

Gas, oil, grease, tar, lacquer, and other flammable chemicals. The first thing you should do with any chemical you're unfamiliar with is read the safety data sheet (SDS). The SDS will show you proper handling to avoid fires but also give you fire fighting recommendations. Some chemicals could require special fire fighting techniques. While you can't be an expert firefighter knowing your surroundings and chemicals can help you assist emergency responders with the correct information to properly respond. Always store chemicals to manufacture's specification.

Type C: Electrical

Electrical equipment, fuse boxes, circuit breakers, machinery, lights, appliances, etc. The most common way for you to be involved in an electrical fire would be getting a power source wet. This could be power outlets, lights, machinery, breaker boxes, appliances or any other sources of electricity. If you notice exposed electricity on a job, get the homeowner or supervisor involved. Keep water away from sources of electricity at all costs. Be sure to cut the power and tape off the source completely if you can't avoid it. Even though some tools might not be conductors, it's common for tools to be wet in this industry. Wet tools regardless of their textile can end up shocking you as well as causing a fire. If an electrical fire starts (usually noticeable by smoking) immediately cut the power and call emergency responders.The fire could end up starting inside a wall and should be investigated. Do not put more water on it unless the power is completely off.

Type D: Combustible Metals

Magnesium, Lithium, Titanium.

Type K: Cooking

Oils, grease, and other cooking media usually found in commercial kitchens. -

Deciding to Fight

If you decide to fight the fire then consider what kind of fire it is when choosing the appropriate extinguisher. -

-

Extinguishers

Extinguishers are labeled with the fire type it's approved for so you can make a quick decision on using it. Get yourself and others to safety. If it's a type A fire then you can put water on it. If it's type C you can also put water on it if the electrical components of an extinguisher below. source has been turned off completely. Most fire extinguishers will be rated for a single "type" and some are rated for "ABC" fires. Hopefully the extinguisher is clearly labeled so you can make a quick decision on using it safely. This is why it's so important to know where, what kind, and how to use your extinguisher before you have to use it in an emergency. See the -

-

To operate an extinguisher:

Always use the PASS Technique.

Pull: the safety pin.

Aim: Stand 10ft back and aim the nozzle at the fire's base.

Squeeze: Squeeze the trigger/handle to release the extinguishing agent.

Sweep: sweep the extinguisher at the fire's base until it is completely out. -

When a Fire Starts

- Stay calm, you're not effective if you panic.

- Try to put it out immediately, if possible. If not, follow the next steps.

- Make sure everyone is alerted and away from the fire.

- Do not stop to collect valuables.

- If it's smokey stay low in the building.

- Shut doors to stop the spread of the fire on your way out.

- Touch closed doors with the back of your hand to check for heat.

- If the door is hot the fire is probably in there.

- Do not use elevators, use the stairs.

- Be ready to communicate information to the fire crew.

- Don't go back in the building.

If Someone Is On Fire:

STOP, DROP, ROLL

If you're near a water source then get to the water source. If someone else is on fire try to suffocate the fire from oxygen with a blanket or get them to water. Do not spray the person with a fire extinguisher unless it's only water. Doing so could blind or suffocate them. Remove all hot or burned clothing and jewelry.

-

First Degree Burns

- Put under cool water (not cold) to cool burn.

- Protect the burn with sterile non-adhesive bandage.

- Do not use ointments in case of infection.

-

Second Degree Burns

- Put under cool water (not cold) to cool burn.

- Do not use ointments in case of infection.

- Do not pop any blisters.

- Protect the burn loosely with sterile non-adhesive bandage.

- Victim should see a doctor.

-

Third Degree Burns

- Call 911, check their pulse, and breathing and do the following.

- Protect the burn loosely with sterile non-adhesive bandage.

- DO NOT put water or ointments on the burn.

- Prevent shock by having victim lay down, elevate their feet 12 inches, elevate burn above heart, and cover them with a coat/blanket. Do not put a pillow under their head if it's a neck burn.

- If it's a facial burn have them sit up.

-

Fire Watch

A fire watch is an individual who watches a project and the area after the project to protect against a fire. The fire watch should stay around after the project for at least 30 minutes to be sure there are no more risks of a fire. These are especially common on projects that include welding, cutting or other hot work. First step to being a fire watch is assuring the area is clear for the project to begin and safe from immediate fire threats.

- Be hands free at all times.

- Be off of your phone.

- Do not be distracted by others.

- Focus on your surroundings and the work being done.

- Communicate with your coworker at all times.

- Know what kind of extinguisher you have.

- Do not have any other responsibilities.

-

Electrical Hazards

Introduction

Employees are regularly exposed to electricity on the job. Exposure could lead to electric shock, electrocution (death), burns, arc flashes, fires, and explosions. Electricity is a hazard that shows no mercy and can leave a worker severely injured or dead in seconds. Electric shock can range significantly in feeling and effects on the body while electrocution means death from electric shock. The flow of electrons through a conductor is known as the current. A conductor is something that carries electricity and an insulator is something that won't carry an electrical current.

Conductors

- You are a conductor.

- Water, especially with high mineral content.

- Metals, gold, silver, copper, steel, brass, aluminum, etc.

- Carbon Fiber.

Insulators

- Rubber

- Glass

- Oil

- Diamond

- Plastic

- Dry Wood

- Fiberglass

During your work you should assume and work as if everything you touch conducts electricity. Even a wet insulator could become conductive on a worksite. Electricity is always looking for a path and it can even jump if you or the equipment become the easiest path (conductor). The safest way to avoid this situation is by grounding equipment or taking safety precautions to become the ground.

Grounding

Grounding equipment means to create a path from the equipment to the ground, usually through metal. Creating this path could save a worker from injury or death if the equipment were to become energized. The electrical current will have an easier path than the worker. If a worker were to hit an overhead power line with a pole or a ladder, that worker would most like become a ground for the electrical current and the results would most likely be electrocution (death).

Electrical Hazard Scenario

A worker is driving to a job site. Due to the wind, a power line tell onto his car, causing him to slam on the breaks. The worker is uninjured, sitting in his car, and can see power lines laying on his car. Let's go through some options the worker could take.-

A. The worker assumes the lines are live and wants to get away from his vehicle. He gets out of the vehicle, with one hand on the door and puts his feet on the ground. Unfortunately his car was energized and the worker became the ground for the electrical current from his energized car to the ground and was killed instantly. The car was insulated through rubber tires until the worker completed the circuit.

B. The worker assumes the lines are live and instantly calls emergency services. He doesn't move, doesn't touch any metal in his car and waits for emergency responders. Once first responders arrive they instruct him to safely exit the vehicle after confirming the lines are no longer live.

Obviously the correct answer is B. The worker stayed calm, called first responders and followed safety practices for dealing with electrical currents to the best of his ability. Now let's say it was the same scenario but a fire broke out from the fallen lines. The worker knows about electrical currents and safety but feels he needs to get away from the vehicle to avoid burning. In this scenario the worker should:- Remove any loose clothing that could be in the way.

- Put his hands at his side, and jump as far away from the vehicle as he can. He should not be touching the car when his feet touch the ground.

- Keep his feet close together and shuffle or hop away until he's at least twenty feet away. It's more important to keep your feet together than how far you jump to limit the ability of electricity to run through your body. Don't over jump and cause yourself to lose balance.

Preventing Electrical Hazards

- Treat all poles, ladders, tools, and equipment as if they're conductors and avoid electricity.

- Keep work areas and walking paths free of electrical chords.

- Do not use electricity in wet conditions.

- Inspect chords and power equipment before use.

- Use the right tools for the job as designed by manufacturer.

- Unplug or power down equipment when not in use.

- Store power equipment in safe and dry areas.

- Remove unsafe chords and power equipment from job site and apply a warning tag for others.

- Do not overload circuits by plugging in too many power tools.

- Do not yank on chords to move or unplug them.

- Never carry a tool by the chord.

-

Voltage Tester

Voltage testers are cheap tools that can measure the presence or absence of an electrical current. Using a voltage tester must be done to be sure the correct break is turned off and it's safe to proceed with work. Each tester works slightly different so read the manufactures recommendation for proper maintenance and operation. Test the device on a live source to be sure it's working correctly and picking up a current. Once you know it's working properly, you'll know if there is a current or not. -

-

Taping Off Plugs

After using the lock out, tag out method, and you confirmed the absence of a current with a voltage tester, you may need to tape off the source. This is common when working with water and a plug or an electrical source can't be avoided. Never attempt this on a live circuit.- Tape the bottom part of the plate to the wall. Then tape vertically from left to right. Always start at the bottom and work your way up to create an overlapping pattern that will shed water.

- Continue your vertical taping until the plate is completely covered. When finished with the vertical taping, cover the top with horizontal tape to create a pattern to shed water.

- Finally, starting at the bottom first, run horizontal tape from the bottom to top to create a shedding pattern for water to run off.

After all these methods are in place, you should still try to avoid getting this area wet as much as reasonably possible. Before turning any power back on, the tape should be removed and the plug should be checked for moisture. When unsure, always leave the power off until it can properly dry or call an electrician. Turning on a wet electrical source could start a fire, cause a shock or even electrocution. -

Shock Effects

Primary

Muscle pain/contractions, inability to let go, difficulty breathing, respiratory paralysis, cardiac arrest, tissue/nerve/organ damage and death (electrocution).

Secondary

Falls

Falls are a common problem after workers are electrocuted. Always have a fall harness on when needed and other PPE to safely complete the task.Burns

Electrical Burns

These types of burns are from the electrical current running through the body. They are internal and effect body tissue or the heart.

Arc Flash Burns

These burns are similar to a severe sun burn from an arc flash or sunburn. Welders who use arc welders can look severely sunburned if they're not wearing the proper PPE to cover their body.

Thermal Contact Burns

This is from physical contact with a hot electrical source similar to a burn from a hot pan.

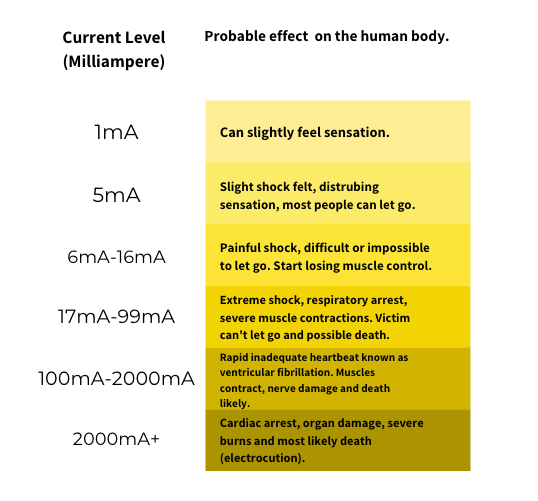

Voltage Vs. Amperes

Voltage

Is commonly mistaken on what kills you. Voltage is the force at which electricity moves.

Amperes

Also known as current or amps is referring to how much electricity is present.

Think of the two as a garden hose. Water pressure (voltage) and water volume (current or amps). If the amps are high they can still kill you even though the voltage or flow may be low. A taser works opposite, with high voltage but low amps causing someone to be stunned instantly and aggressively but hopefully no lasting effects.

The effects of shock and potential electrocution.

-

Personal Protective Equipment(PPE)

What is PPE

Personal protective equipment is anything you wear that protects your body from hazards. PPE should be provided by your employer and maintained, inspected, and worn by you and other workers. Before starting a task you should plan what PPE you need and inspect it to make sure it's up to standard for the job. Make sure your PPE isn't creating an additional hazard by wearing them. For example, headphones with loud music is not sufficient protection for hearing protection. This could result in the worker unable to hear moving equipment or another hazard. PPE can include but not limited to gloves, helmet, hard hat, boots, eyewear, respirator, visibility vest, hat, fall harness, ear muffs, etc. Your clothing or uniform is also part of your PPE. Make sure you're wearing the correct clothes to keep you safe. This could mean extra layers in the cold or clothing to keep your body covered on a hot day. Think of every different kind of hazard on your job such as biological, chemical, thermal, physical or any other hazard you might face.

Head Protection

Head protection is important in any work environment. From falling objects to weather, head protection can keep the user safe from unnecessary hazards.-

Hat

Hats should be used for dermal protection against the sun. This simple PPE can protect the worker from short term sunburns and long term skin issues.

Beanie

A beanie should be worn in colder climates to keep the body temperature well regulated.

Hard Hat

Hard hats should be worn when there are hazards from overhead objects that could fall, or if a worker is in danger of hitting their head. Hard hats should be the proper size and tightened to the worker's head.

Helmet

A helmet differs from a hard hat because of the chin strap. Helmets are better for workers who have the same hazards as a hard hat but also a fall hazard. The strap will provide additional support in the event of a fall.

Eye Protection

All eye protection should meet the American National Standard Institute (ANSI) regulations. This is usually referring to impact resistance and splash resistance standards.-

Safety Glasses

Safety glasses should be worn to prevent debris from impacting the eye. Most safety glasses won't protect against spraying or chemical splashes unless specifically designed with splash guards.

Goggles

Goggles should be worn when there is a spraying or splash hazard from chemicals or other substances.

Face Shield

A face shield should be worn when there is a high hazard of flying debris. Face masks usually don't protect against chemical and biohazards, unless specifically designed to seal around the face, with a respirator.

Emergency Eye Wash

Controlled workplaces should have emergency eyewash stations near by to rinse your eyes out. When working on the field, this isn't always the case. Before working with or around chemicals, make sure a safety data sheet is nearby or you're familiar with the product. This will give you information on what to do when the product gets in your eye. You may also need to rinse your eyes from debris getting in them. When washing your eyes:- DO NOT RUB THEM.

- Hold your eyes open.

- Look directly into the low water pressure source.

- Flush for 15 minutes

- Seek medical attention.

Respiratory Protection

Respirators are used to prevent individuals from inhaling harmful airborne hazards and/or used to provide clean air/oxygen from an uncontaminated source. All respirators cover the nose and mouth. Some respirators cover the entire face and some even the entire head. Below we'll look at respirator vocabulary, different styles, types, and what they might be used for so you can properly protect yourself. People who suffer from lung diseases, asthma, claustrophobia, emphysema, and other conditions may not be able to safely wear a respirator. Things like facial hair, scars, facial/head surgeries, weight loss/gain, piercings and other factors call also play a part in how your respirator might fit. You should retest and refit your respirator if anything on your face has changed, even slightly. Be sure to consult a doctor or respirator fit specialist if you're having trouble getting a good seal for a fit test or suffer from a condition making a respirator unsafe.-

Tight Fitting Respirator

These respirators create a tight seal around the users face. These are broken down into quarter mask, half mask, and full face piece. A quarter mask covers the nose and mouth wile the half mask also drops down and seals under the chin. The full face piece covers the entire face from under the chin to the hairline, providing safety for the eyes.

Loose Fitting Respirator

These respirators are designed as hoods, helmets, or full suits that cover the head completely. These are positive pressure respirators which means there's air pressure inside the hood greater than the surrounding environment. This keeps out contaminated air out, because there's a consistent flow outward from the respirator. Positive pressure can come from a small motor filter, air supply hose, or from a compressed air tank.

Airborne and Respiratory Hazards

Hazardous atmospheres can be from an oxygen deficient atmosphere (under 19.5%) or airborne particles such as vapors, gasses, fumes, dust, mists, or smoke. These airborne hazards can be created or become exposed by workers doing work in these areas. It's important to plan your work so you can avoid creating extra hazards and protect yourself beforehand.-

Asbestos

Asbestos is a silicate mineral that can be inhaled if the dust is kicked up. The dust or particles attach to your lungs and cause scaring and potentially cancer. It is best if left undisturbed. Before the 80's, asbestos was used in thousands of building products. It most likely won't harm you, unless you work with it - meaning you're turning it into dust. If you're in an older house and it seems to be deteriorating while you're working, or kicking up dust, use precaution. The most common place it could be found for a window cleaner is siding, drywall, sheet rock, window putty, or interior walls. In most countries, asbestos is illegal. Asbestos is not something to worry about in newer construction. Either way, if dust is present, protect your lungs. Asbestos should only be handled by qualified individuals with proper training.

Exhausts

Exhaust systems create dangerous atmospheres. Exhaust fumes from engines create poisonous carbon monoxide (CO) gases that are odorless, and colorless. Mild exposure can lead to headaches, dizziness, nausea and fatigue. Continued exposure can lead to unconsciousness and suffocation within seconds because it displaces the oxygen in the blood resulting in oxygen deprivation in the heart, brain, and other vital organs. Never run any equipment indoors or poorly ventilated areas that have an exhaust, even for a couple seconds. This could quickly create a deadly atmosphere.

Air Purifying Respirator

These respirators filter the surrounding atmosphere and remove contaminants. If these are used in atmospheres that aren't safe, the consequences could be deadly. Air purifying respirators are broken down into two more categories depending on the hazard. Particulate and gas/vapor removing respirators, which can also be combined.-

Particulate Removing

Particulate removing respirators are known as filters. Filters trap particulates such as nuisance dust, fumes, mist, radiation, toxic dust, asbestos dust/fibers, and any combination of these before the user can inhale them. These respirators are commonly referred to as face piece respirators, disposable respirators, single-use respirators, or dust masks and can be one time use or have replaceable filters. The filters cannot be cleaned, sanitized, or disinfected and should be replaced with a new filter after use. Disposable masks and/or filters should be disposed of properly after use and never shared between individuals. If the filter is replaceable, then do so before the expiration, after heavy use, when there isn't a good filter seal, or when something doesn't look right during the inspection. Sanitize reusable respirators after each use. These respirators can be non powered, which means the air is pulled in and pushed out simply by the user inhaling and exhaling. Alternatively they can be a powered air-purifying respirator (PAPR), which uses a small motor to pull in air through the filter and supplies it to the user.

Gas & Vapor Removing

Gas & vapor removing respirators remove particulates as well. This is done with the use of canisters or cartridges. The canister or cartridge will remove particulates and absorb the gas and/or vapor before the worker can inhale them. This type of element remover expires and needs to be replaced before the expiration, after heavy use, when there isn't a good filter seal, or when something doesn't look right during the inspection.

Atmosphere Supplying Respirators

These respirators provide air to the user from an uncontaminated source. This is needed in atmospheres that are dangerous beyond removing gas, vapors, and particulates.

Self-Contained Breathing Apparatus

A self-contained breathing apparatus (SCBA) similar to a self-contained underwater breathing apparatus (SCUBA) is a common method used by firefighters or others entering an unknown atmosphere. This gear allows the user to carry clean air in a tank, usually on their back, into the contaminated area. The tanks are connected to the respirator through an air supplying hose. Since the air is limited to the tank the user can only be in the contaminated atmosphere for a limited period.

Air-Supplied Respirator

The other source could be an air-supplied respirator which is a hose connected to a stationary source that's supplying the user with air from an uncontaminated source. Some setups could also use a combination of these two methods. Each of these atmosphere supplying respirators involves air flow/pressure control, extensive training and qualified individuals. Do not attempt to use these after this module. atmospheres needing these respirators should only be entered by a qualified individual.

Positive and Negative Air Pressure

Negative air pressure respirators are operated by the user pulling in air and pushing it out by inhaling and exhaling. These require a complete seal around the face to avoid the user from pulling in contaminated air. The alternative would be a positive pressure respirator which has constant air pressure inside the respirator from a motor filter, air supplied hose, or a compressed air tank. This positive pressure allows the user to remain safe without a sealed respirator design because the contaminated air is being pushed out by the filtered air that's being pumped into the respirator. -

Air Quality Index

The air quality index is a chart used to notify people of poor air quality. These numbers are on most weather apps to inform people of the quality of the air in their area. This is helpful when deciding to use a respirator for typical weather air quality conditions. As a worker be aware of how you can change the air quality conditions so you can prepare with the correct PPE.

Immediate Danger to Life or Health (IDLH)

This term is referring to atmospheres that have contaminants or gases that could cause immediate health issues or death to someone entering. These atmospheres need atmosphere supplying respirators. These atmospheres can have a lack of oxygen so purifying the air in the in an IDLH atmosphere doesn't change the quality of the oxygen in the air. If the area is a confined space or has an unknown atmosphere it should always be treated as IDLH.

Confined Spaces

Confined spaces are areas that are difficult for a human to enter or exit commonly known as but not limited to storage tanks, process vessels, towers, drums, tank cars, bins, sewers, septic tanks, utility tunnels, manholes and more. For safe oxygen levels the air needs to be at least 19.5% for humans.

Confined spaces are commonly oxygen deficient and can be and IDLH atmosphere. Confined spaces should only be entered by qualified individuals who are trained and up to local safety requirements.

-

Filtering Facepiece Respirator

These are commonly known as N95 masks. They're disposable air filtering respirators. This will not protect you in an IDLH atmosphere or from gas or vapors. These are great for airborne particles. 95 refers to the rating percentage of particles it can filter out. These are also designed in applications that are reusable with replaceable filters.

-

-

Elastomeric Half Facepiece Respirator

These are great for airborne particles as well as filtering out chemicals, vapors, and gases. The filter canisters can be replaced so you can use the same respirator while replacing the filter. The filters should be a high efficiency particulate air (HEPA) filter, which have a higher rating than the N95. These will not protect against an IDLH atmosphere.

-

-

Elastomeric Full Facepiece Respirator

These are great for airborne particles as well as filtering out chemicals, vapors, and gases. The filter canisters can be replaced so you can use the same respirator while replacing the filter. The filters should be a high efficiency particulate air (HEPA) filter, which have a higher rating than the N95. A full facepiece will help the user avoid getting hazards into their body and protect their eyes. One drawback is that these can fog up in certain scenarios. These will not protect against an IDLH atmosphere.

-

-

Powered Air Purifying Respirator

These respirators use a small motor to pull in air through a filter to provide the user with filtered air. These are great for airborne particles as well as filtering out chemicals, vapors, and gases. The filter canisters can be replaced so you can use the same respirator while replacing the filter. The filters should be a high efficiency particulate air (HEPA) filter, which have a higher rating than the N95. A full facepiece will help the user avoid getting hazards into their body and protect their eyes. One drawback is that these can fog up in certain scenarios. These will not protect against an IDLH atmosphere. Before starting work be sure that the motor is fully charged or has new batteries.

-

-

Supplied Air Respirator

These respirators use a connector hose to attach the respirator to a clean source of supplied air. This falls under an atmosphere supply respirator and provides clean air from an uncontaminated source. These require special training and a qualified individual.

Since the air is coming from a separate uncontaminated source the mask could protect the user against an IDLH. These masks should be used and setup by qualified individuals.

-

-

Self-Contained Breathing Apparatus (SCBA)

These respirators use a tank of compressed air to supply air to the individual. These are most commonly used by firefighters or in marine applications to protect against IDLH atmospheres. These require extensive training and should only be attempted by someone with such, who is a qualified individual.

-

-

Loose Fitting Hood Respirator

These are a powered air purifying respirator that don't have a tight seal around the user's face. This allows the fit to be more universal for users and easier to put on or take off. These respirators will not protect a user in an IDLH atmosphere. These can also create limited sight issues because the hood doesn't perfectly move with the head.

-

-

Hazards

Respirators are designed to keep you safe, but they can also create other hazards. Before entering or creating a hazardous atmosphere have a questioning attitude, is there a better way? Can I avoid going in the area? For hazard control remember PPE is a last resort because getting rid of the hazard altogether should be top priority.

Emergency Getting Out

You've donned a gas mask to protect yourself against certain hazards. Gas masks can create other hazards, especially for worker's not used to them. It's common for the masks to fog up and make it difficult to see. This can lead to a feeling of claustrophobia and panic. Your first priority should be to get to a safe area and remove the gas mask. In an IDLH atmosphere you should never remove your gas mask to get out. In other areas it may be your best shot at survival. Try to keep the respirator on while exiting unless it creates a greater hazard without removing it. Only you can make the decision, make it quickly and try to alert others in the area so they can help you exit. -

Hearing Protection

Hearing hazards are different than a lot of other hazards because consistent exposure can slowly become long term and permanent damage. The safety industry has come up with the four "P"s of hearing hazards.- Preventable

- Painless

- Permanent

- Progressive

Make sure you find adequate ear protection before starting up equipment. There are disposable earplugs made out of foam and pvc as well as earmuffs which are reusable. Headphones with loud music is not proper hearing protection, and can cause hearing damage as well. Sound is measured in decibels. When the work volume reaches 85 decibels or consistently below but near that, then hearing protection should be worn. Here are some examples of what certain decibels might sound like. These numbers can vary significantly based on many factors.

30 dB - Whisper

60 dB - Typical Conversation

85 dB - Pressure Washer

100 dB - Leaf Blower

120 dB - Rock Concert

140 dB - Gun Shot

Decibels at or over 120 dB could result in immediate and permanent damage. Always choose to wear hearing protection. Consistent dB of 85 can result in permanent damage.

Noise Reduction Rating (NRR)

The noise reduction is a rating placed on hearing protection to provide the user with the amount of decibels the hearing protection reduces. Hearing protection should be up to the American National Standard Institute (ANSI) inspection standards.

Time-Weighted Average (TWA)

The time-weighted average is measured in decibels to calculate the exposure over an eight hour shift. This should be expressed on the labels of equipment, usually in decibels so a worker can pick the proper NRR.

TWA=dB-(NNR-7)

Example: A pressure washer has a TWA of 110dB. Your hearing protection has an NRR of 29. You'll want to subtract 7 from the hearing protection, this is like a buffer to make sure the protection to sufficient.

TWA=110dB-(29-7)

TWA=88

Our goal should be to get this number under 85, so in this situation double hearing protection would be required to keep the worker safe from long term hearing damage. You can continue to make calculations on dual hearing protection based on the needs of equipment you're using along with the NRR of the hearing protection. Keep in mind that administrative controls such as long hoses can help workers stay farther away from equipment therefore reducing the TWA as well as the hearing protection.

-

Ear Plugs

Ear plugs are a common PPE for ear protection. These are usually disposable after a few uses. Read the user manual for recommended use and when to dispose. Ear plugs work well when double hearing protection is needed to get the desired NRR because they're small and fit inside other ear protection. -

Ear Muffs

Ear muffs are reusable hearing protection and common when working around power tools. They're easy to adjust and fit to different users. They also work well covering ear pugs when dual hearing protection is needed. -

Noice Reduction Rating (NRR) Label

The noise reduction rating labels are placed on hearing protection PPE or on the packaging to notify the user how many decibels the protection will cover. This is a very important label when deciding which hearing protection to cover the noise hazard you're dealing with. Never assume the noise reduction rating when the label isn't present. This could lead to permanent hearing damage. -

-

Hand Protection

Your hands are one of your greatest assets in life. Hand accidents are common in the workplace because they're involved in almost every task. Don't take healthy hands for granted and make sure they're protected. Hand injuries can include the hand, fingers, and wrist. Injuries can include breaks, fractures, sprains, dislocations, burns, frostbite, amputations, etc.

Traumatic

Traumatic injuries can be from blows or cuts to the hand. Good gloves can protect your hands from cuts, punctures, and other injuries. When working around machinery make sure your gloves are tight fitting and won't get snagged into the machine. Your personal protective equipment should protect you and not create additional hazards.

Contact or Exposure

Being in contact with hot/cold objects, chemicals, biohazards, electrical sources, etc. can create dangerous hazards for hands. Make sure your gloves are approved for the task being performed. Gloves that would protect you from electrical hazards could be completely different than a glove that would protect you from chemicals or biohazards. A glove that protects you from one chemical could have a dangerous reaction with another chemical. When dealing with contact hazards make sure you read safety data sheets of chemicals and choose the best glove for the hazard. There are several different types of disposable and reusable gloves. Gloves can be made out of the following and can have different reactions.- Nitrile

- Vinyl

- Latex

- Neoprene

- Butyl Rubber

- Viton

Repetitive Motion

Using your hand in the same or constant motion for long periods can result in short term blisters or long term permanent damage, usually in hand ligaments. If your hand feels numb, tingling, chronic pain, acute pain, inability to grip, weakness, etc. then you should stop immediately. Gloves might not protect against this hazard because your hands are still active even if you're wearing gloves. To remedy the hazard go through the hazard of controls. Can you eliminate or substitute the hazard? Are there engineering controls the make the motion easier on your hands? Can you use administrative controls to rotate workers and limit the need of repetitive motion? -

Foot Protection

Similar to your hands, your feet are important assets in your daily life. A small foot injury could result in time off work, disrupt your daily routine or worse. Keep your feet healthy with proper footwear for the task so you can continue to do your job safely. Keeping your workplace clean and organized will help your feet from stubbed toes or falling objects that could crush someone's foot. A shoe for the task could mean completely different things. If you're at risk of your tow getting crushed then steel toed boots might be best. If you're working in wet or slippery conditions, a waterproof slip resistant shoe might be best. Try to break in your shoes before work to avoid blisters or injuries by wearing them for small periods for your shift.

Traumatic

Traumatic injuries can be from blows or cuts to the foot. Good shoes can protect your feet from cuts, punctures, and other injuries. Make sure your shoes are the right size and correct type for the hazard. Steel toed boots can help from falling objects or blunt force like from a blade. Without this protection you could be facing severe cuts, crushed toes/feet or even severed toes.

Contact or Exposure

Being in contact with hot/cold objects, chemicals, biohazards, electrical sources, and more can create dangerous hazards for feet. Make sure your shoes are approved for the task being performed. Regular and consistent exposure to something as harmless as water can result in fungus, trench foot, immersion foot syndrome, severe blisters, cracked feet, and other issues. Keeping your feet dry and away from the elements of your job is important. There are tons of different styles and fits to keep your feet dry and safe at work.

Repetitive Motion

Being on your feet all day or working on uneven surfaces can be hard on not only your legs, but all the way up to your hips and spine. Having good shoes can help mitigate long hours on your feet and reduce the stress on your body. If your shoes lack proper foot support then it may be time to replace the inserts with new ones.

Associated Hazards

Besides protecting your feet your shoes can also protect you from other hazards and injuries. Going on roofs, working on slants, or in slippery areas can result in slipping. A slip could mean back, head, neck etc. injuries or even falling from an elevated platform. Working in shoes that are too big could result in tripping and lead to more serious injuries. Make sure you have the right type and fit of shoes for your personal use.

Shoe Cleats

Cleats are adaptors for the bottom of your shoes. They can give your shoes the proper grip for the task you're facing. These are popular for roofers, snow/ice work, fishermen, athletes and other professionals. It allows the improper shoe to become the right shoe. If your company provides cleats for specific work, then inspect them and use them for your safety. These are also commonly known as Korkers, which is actually a brand. -

PPE Maintenance

PPE should be inspected before and after each use. If your PPE doesn't look right then don't take chances and remove it from service. Make sure that others don't use the PPE either. When inspecting something, make sure you understand the function so you can understand if it's working properly. Look for deterioration, punctures, tears, breaks, or signs of unsafe wear. Clean your PPE after each use to ensure longevity and make sure it's properly stored in a dry, clean place.

Responsibilities

Employer- Provide required PPE.

- Train on required PPE.

- Enforce cleaning, inspecting, replacing and documenting.

Employee- Listen and ask questions regarding PPE training.

- Wear the PPE when required.

- Clean, inspect, replace, and document.

- Report hazards or PPE damage to supervisor

- Be safe on the job and encourage others to do the same.

- Stop Work when something isn't right.

If you feel you have a full understanding of this module, proceed to the test. Once you complete the test, you will be redirected back to the main module page.