Water Fed Window Cleaning

What is water fed window cleaning? It's the safer, faster, and easier alternative to squeegees and scrubbers for getting spotless glass! Check out all these high quality tools to get the job done, or keep reading below.

What is Water fed window cleaning?

Water Fed Window Cleaning has seen some of the industry's greatest innovations and technology at work, making it a more modern and safer method of cleaning windows. Water fed window cleaning utilizes pure water. But what makes pure water so effective? Pure water has a TDS of 0, which means it’s free from impurities, minerals, and contaminants. Let’s go over the benefits of waterfed window cleaning, the science behind it, and what equipment you need to get started.

There are many benefits to water fed window cleaning over traditional methods. For one, it’s safer due to the elimination of ladders. Users can easily clean windows up to 75 feet high with their feet safely on the ground. How amazing is that? This results in increased safety for you or your employees. Waterfed window cleaning is not only safer, but it’s also faster as well. It can easily cut your job time in half while still creating streak-free results. Being able to reach those previously inaccessible windows is also a huge benefit. Ultimately, pure water systems allow for better results with minimal inconvenience to your customers.

Do water-fed poles leave streaks?

Waterfed poles utilize pure water, so the short answer is no. To understand exactly why water fed window cleaning works, you must first understand the science behind it. Regular tap water, as it naturally exists, has tiny dissolved particles in it. Once the water dries on a surface, those particles become the spots you see left behind. So, if you were to clean with normal tap water, it would result in the glass having a milky white residue left behind. It’s important to understand what TDS means. TDS, or total dissolved solids, is the measurement of those impurities in your water. Determining your TDS is the first step in choosing the right water-fed system for you! You might ask, “What is my TDS?” Check your TDS here.

Your TDS can be considered a simple measurement of water quality or how soft or hard the water is. Measuring your TDS is an important step. Your TDS will dictate what waterfed equipment you need and which will be most cost-effective in the long run. To clean windows spot free, the TDS of your water needs to be at 0. You need pure water or water without any mineral content, which will leave windows perfectly clean when it dries. Pure water automatically absorbs the dirt leaving windows 100% spot free.

How do you get pure water?

A pure water system can be as basic as a single-stage system, like a DI Tank, or as advanced as a multi-stage system. You can purify your water with either, and each method will get you to a TDS of 0. Which method you use (and which is the most cost-effective to you) all depends on your incoming water quality or TDS. For example, if your TDS is below 100, you are considered to have softer water, and a simple DI tank-based system will work well for you. On the other hand, if your TDS is over 100, you have hard water, and a multistage system is necessary. A DI tank is not a cost-effective purification method if you have hard water. Be sure to check out our entire collection of pure water systems.

Waterfed systems are designed to optimize your window cleaning process, saving you valuable time and effort. Waterfed window cleaning doesn’t have to be overwhelming! With our high-quality waterfed poles and equipment, you can easily tackle multi-story buildings, commercial properties, residential homes, or solar fields with exceptional efficiency. No more wasting time climbing up and down ladders or struggling with hard-to-reach obstacles. Experience the speed and precision of pure water, and take your window cleaning game to the next level.

What is DI resin?

Let's take an even closer look at two of the purification methods we mentioned above: single-stage systems versus multi-stage systems. Deionization Resin, commonly referred to as DI Resin, is honey-colored plastic beads charged with chemicals that remove the minerals and impurities from the water. DI Resin is 100% necessary to reduce the Total Dissolved Solids (TDS) to zero and is the last stage of an RO/DI unit. Standard DI tanks or systems with resin are great for areas with soft water, solo operators, or infrequent users. It can be used as a standalone filtration system or as the final step in a multistage purification system. DI Tanks are much cheaper than multistage systems, but again, a DI Tank will only be an appropriate option if you have a lower TDS of under 100. If you have a TDS on the higher end of the spectrum, you will burn through your resin much faster than if you start with a lower TDS. Using a DI-only system may seem cheap up front, but the DI resin doesn't last long, over time, you will spend a fortune refilling the tank. Ultimately, you may save some money upfront, but in the long run, this would be a poor investment. It all comes down to water quality.

What is a multi-stage system?

Now, onto multi-stage systems. A multistage system is best if you have hard water or are using your system frequently or even daily. A multi-stage system will cost a lot more upfront, but you will be changing the DI resin much less frequently, and it will cost less. Multi-stage systems are a better long-term investment for many customers. They are a great option for either a residential or commercial window cleaning company. If you need a complete setup that is ready to go right out of the box, consider a complete pure water package.

Generally, the 4 components of a multistage system include a sediment filter, carbon filter, RO membrane, and DI resin. Both the carbon and sediment filters protect the RO from chlorine and sediment. The Carbon Filter should be replaced about every two months. Both filters are inexpensive, and it’s always a good idea to have extras on hand. The RO Membrane’s main purpose is to lower your TDS to a level that will extend the life of your DI Resin. It can effectively remove 90% of the TDS from the water before it moves down the line to your DI. The RO membrane is the largest and most expensive filter. For this reason, your RO membrane is extremely important. With proper care, your RO membrane will last for many years and can run you anywhere from $350 - $600, depending on the make and model of the system. Finally, the DI is the last stage of defense and is changed as needed. It removes the remaining minerals from the water, leaving you with 100% pure water. Since pure water is a cleaning agent, it will dry spot free. If you start to see your TDS creeping up from zero, it’s a good idea to get some resin on order.

What is an "on-demand" system?

Standard DI tanks, systems, and multistage systems are what’s known as “On Demand” Systems. Simply put, they make purified water on demand. You can also look into streamlining your waterfed equipment even further and look into a “tank-based system” such as a Delivery System, or a Truck Mount System. A tank-based system can be filled overnight, and you transport the water in the tank, along with your purification system, right to the job. With this method, you are not dependent on your customer’s water pressure or even the availability of water.

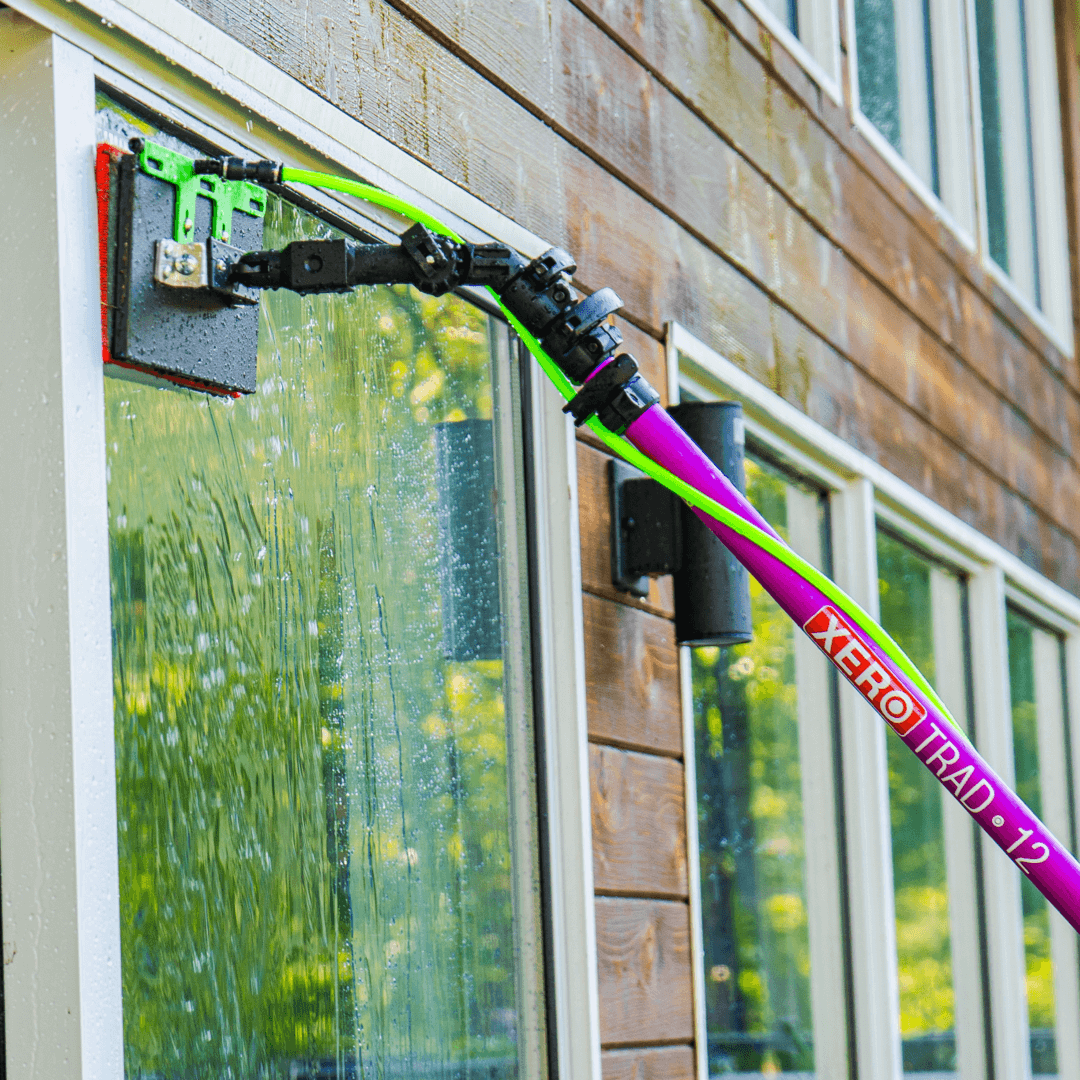

We offer a multitude of water fed poles so you can select the perfect pole for your window cleaning business. You can choose from various materials, such as carbon fiber, high-modulus carbon fiber, and aluminum options. We carry all of the top brands, such as XERO, Pure Water Power, Ova8, and Unger. Here are 10+ Reasons to Buy a XERO Pole which are backed by a lifetime warranty. We also recommend going with carbon fiber water-fed poles due to their lightweight nature and rigidness. Choosing the right pole for you comes down to a few key factors, such as your budget, how high you need to reach, and how often you will be using your pole. Our Understanding Waterfed Poles guide is a great place to start if you want to learn more. By the way, we carry all of the water fed pole parts you need to keep your pole working like new, whether that be pole tips, replacement sections, replacement clamps, etc.

How does water fed pole window cleaning work?

Regardless of which pole you choose, when waterfed cleaning, purified water gets pushed through your waterfed pole. At the end of the pole, the waterfed pole brush has jet configurations, spray nozzles or rinse bars. The water is then applied onto the glass or surface through the jets. The soils and impurities are agitated by the scrubbing of the brush, and the soils are then suspended in the water, ready to be rinsed away by the constant stream(s) of pure water. The pole and brush system get agitated across the glass surface. No detergents or soap are required, just brush the water on, rinse it off, and the result is a streak-free finish. Voila, the glass surface, and frames are dry spot-free!

Now that we've covered waterfed poles and systems, consider adding a waterfed brush to your waterfed equipment arsenal. Most of our customers own several brushes to better prepare for different kinds of jobs. When it comes to waterfed brushes, you can choose between Nylon, Boars Hair, and Hybrid bristles. Full Nylon is gentle, lighter, and great for maintenance cleaning. Boars Hair is heavier but much more aggressive and can clean with fewer passes. Hybrid Brushes (a mix of Nylon & Boars Hair bristles) are extremely popular because they give you the best of both worlds. Every brush comes with a set of jets that can be configured in different ways. This allows water to spray onto the glass or surface. Brushes come equipped with either single jets or dual jets in different configurations. There are two types of jets: pencil and fan. Pencil jets emit a small, circular jet of water, while fan jets emit a fine mist of water and fan out over a larger area.

What waterfed accessories do i need?

There are a few other waterfed accessories you need for pure water window cleaning. Consider adding a hose reel or extra hose to your setup. When it comes to waterfed hose, you want something lightweight, lays flat, is kink-resistant, easy to work with, and has almost no memory. Other water-fed accessories are also available such as goosenecks, TDS meters, waterfed pumps, and replacement filters and housings. Keep your waterfed system working like new with any water fed replacement parts, we carry it all.

If you are considering transitioning into waterfed window cleaning, it can be overwhelming, and we certainly understand that. But worry not, our team of waterfed experts are here to guide you and help you choose the best waterfed setup for you, your budget, and your business. This can also be a hefty investment so if you want to pay in smaller, monthly installments, consider our window cleaning financing program. Whether you buy outright or finance, we carry a full line of pure water window cleaning equipment to make sure you have all of the supplies you need. Don’t hesitate to contact us if you’re ready to discuss waterfed window cleaning!